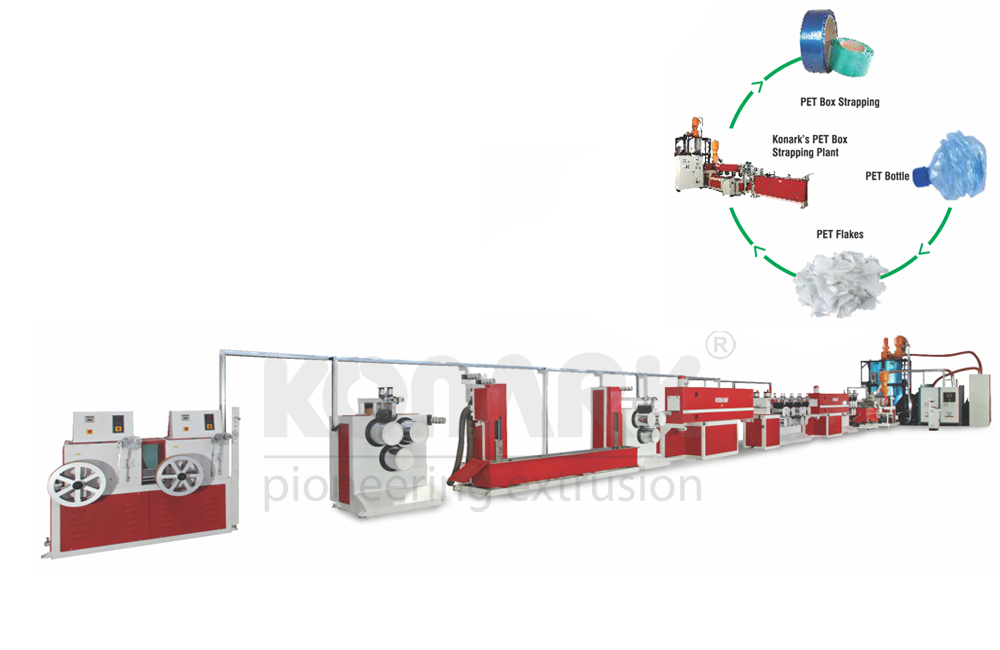

PET (Polyester) Strapping Band Extrusion Line

- Strap Size : 12 mm / 15 mm / 16 mm / 19 mm / 25 mm

- Output Capacity : 100 Kg/Hr to 350 Kg/Hr

- Extrusion lines suitable for processing 100% PET flakes or PET virgin material

- Output range starting from100 Kgs/Hr to upto 350 Kgs/hr

- PLC based dehumidified air dryer with crystallizing system

- Smooth Feed type Nitrided Barrels

- Simple or Barrier type Nitrided Screws

- Jockey extruder for master batch / additives feeding

- Helical gear box with inbuilt thrust bearing

- Hydraulically operated continuous type filter changer

- Melt pump system for uniform melt flow

- Specially designed strapping die head ensuring uniform flow distribution

- Individual die inserts for different strap sizes

- Uniquely designed quenching tank with heating & cooling circuit

- Quenching tank motorized up-down arrangement

- Heavy duty godet roller construction with oil heated rollers

- Individual MTC units for all godet rollers oil heating

- All godet unit driven by hardened gears drive

- Orientation hot air oven with thyrister based heating system

- Embossing roller assembly

- Unique stabilizing hot air oven design and long chilled water tank

- Specially designed winder for PET straps

- High density ceramic type band heaters

- SSR based all heating zones

- Single point synchronization of whole line with AC motors and AC invertor drives

- Bimetallic screw & barrel

- Servo based electronic programmed winder

- IPC based line control with PLC

- Online strap cutting machine

- Water Chilling Plant

- Cotton / Jute Bale Packing

- Metal Sheet, Rods & Coil Packing

- Laminates & Plywood Packing

- Export Palletisatoin

- Paper Industry Packing

- Glass Industry Packing

- Ceramic Industry Packing

- Engineering Industry Packing

- Construction Material Packing

- Textile Industry Packing

| Model | KPTBX/75 | KPTBX/80 | KPTBX/90 | KPTBX/100 |

| Material To Be Processed | PET Flakes | PET Flakes | PET Flakes | PET Flakes |

| Screw Dia | 75 mm | 80 mm | 90 mm | 100 mm |

| Barrel Feed Type | Smooth Feed | Smooth Feed | Smooth Feed | Smooth Feed |

| Strap Size & Lines | 12 mm – 2 Lines | 12 mm – 2 Lines | 12 mm – 3 Lines | 12 mm – 3 Lines |

| 15 mm – 1 Line | 15 mm – 2 Line | 15 mm – 2 Line | 15 mm – 3 Line | |

| 19 mm – 1 Line | 19 mm – 1 Line | 19 mm – 2 Line | 19 mm – 2 Line | |

| Maximum Output | 100 Kg/Hr | 150 Kg/Hr | 200 Kg/Hr | 250 Kg/Hr |

| Winder | Two Station Electronic Winder | Two Station Electronic Winder | Three Station Electronic Winder | Three Station Electronic Winder |

| Machine Connected Load | 225 KW (300 HP) | 265 KW (353 HP) | 375 KW (500 HP) | 475 KW (633 HP) |

| Dimensions ( L x W x H ) Apprx |

115 x 15 x 20 Feet | 120 x 15 x 20 Feet | 135 x 15 x 22 Feet | 150 x 15 x 25 Feet |

*All above specifications are just for an idea and subject to change arising out of continuous product change and improvement.